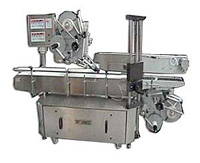

For in-line speed and precision, the Tronics Series 3 from Weber is a system that addresses a wide variety of pressure-sensitive labeling applications.

The Series 3 is available in standard-, medium- and high-speed models. The systems apply front, back, wrap-around, top and bottom labels for the broad range of packaging markets – and for an even wider range of products and packages.

These ruggedly constructed, dependable systems can be configured to handle a diverse selection of package shapes and sizes. And the Series 3 can dispense and apply pressure-sensitive labels from .5 inch high and long to a full 10 inches high and 39 inches long.

Package Flexibility

Package Flexibility

All Series 3 label applicators are equipped with a standard 7.5-inch wide, 10-foot long heavy-duty conveyor and labeling heads that will accommodate up to a 9-inch wide label web (kits for larger labels are optional).

- Product sizes – from vials as small as 5ml to 10-gallon pails

- Product shapes – round, flat-sided, oval/contoured, plus unstable products like syringes, narrow cylinders/tubes, caps and more

- Product materials – plastics, paper products, metals, glass, rubber, ceramic, wood and more

Label Flexibility

The Series 3 handles small labels and large, in varying shapes, and applies them to virtually anywhere on a product or package.

- Label size – from .5-inch high by .5-inch long, up to 10 inches high by 39 inches long

- Label application – front; back; top; bottom; wrap-around (up to 100 per cent); booklet; crescent-shaped (for tapered rounds); one label on two, three or four panels; corner-wrap; two adjacent sides; spot; tamper evident; neck; one, two or three labels on a round product; RFID and more

- Label materials – standard pressure-sensitive paper, clear, Mylar, foil and more.

Product & Label Changeovers

Series 3 labeling systems are extremely user-friendly and easy to adjust when changing products and/or labels.

Conveyor rails plus modules like labeling head(s), wrap-around belt, backing pad, overhead product hold-down and aligning chains all have tool-less adjustments, in addition to quick-reference rulers beveled into the shafts. These design functions provide reference points that ease system operation.

In addition, the Series 3 features simple electronics and touch-pad controls (photo at lower right) that provide a number of unique advantages.

- On-the-fly adjustments – any label head or module can be adjusted without stopping the system; the touch-pad provides the operator with adjustment options

- Job memory – up to 100 jobs can be stored in the system’s memory to expedite changeovers

- Durability – the system’s sealed interface provides protection in chemical and other industrial environments

- On-board software – the Series 3 communicates with all popular PLCs, including Allen-Bradley and Omron. All software for any possible upgrade or option is pre-loaded; no downloading of proprietary software is required

Tronics Series 3 labeling systems from Weber also include an array of miscellaneous features, including batch counting, real-time products-per-minute display, total products labeled, additional inputs and outputs for missing/low label and for integration with PLCs on other packaging and handling equipment.